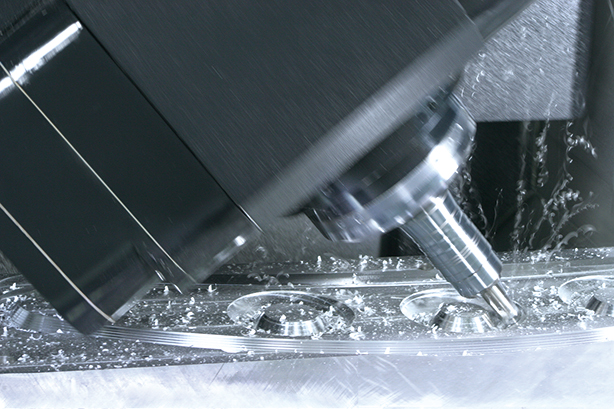

While our vertical machining centers range in size and capacity, we design each one with quality, reliability, ease of operation and safety in mind. Furthermore, thanks to our Production-On-Demand manufacturing philosophy, all of our vertical machining centers incorporate the latest, most advanced milling technology for boosting productivity and growing your business.

Vertical

What is Vertical Machining?

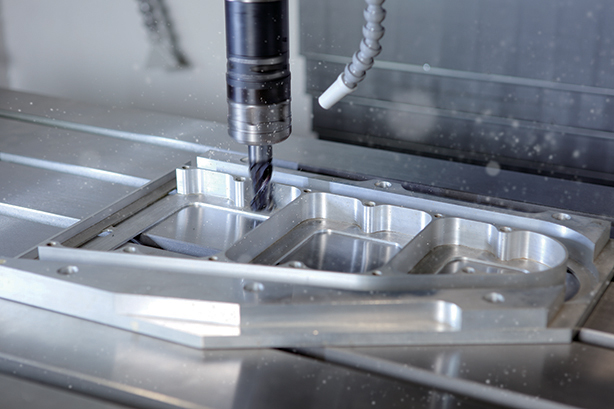

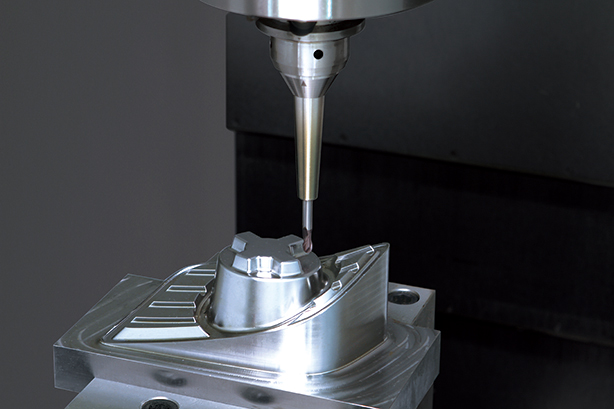

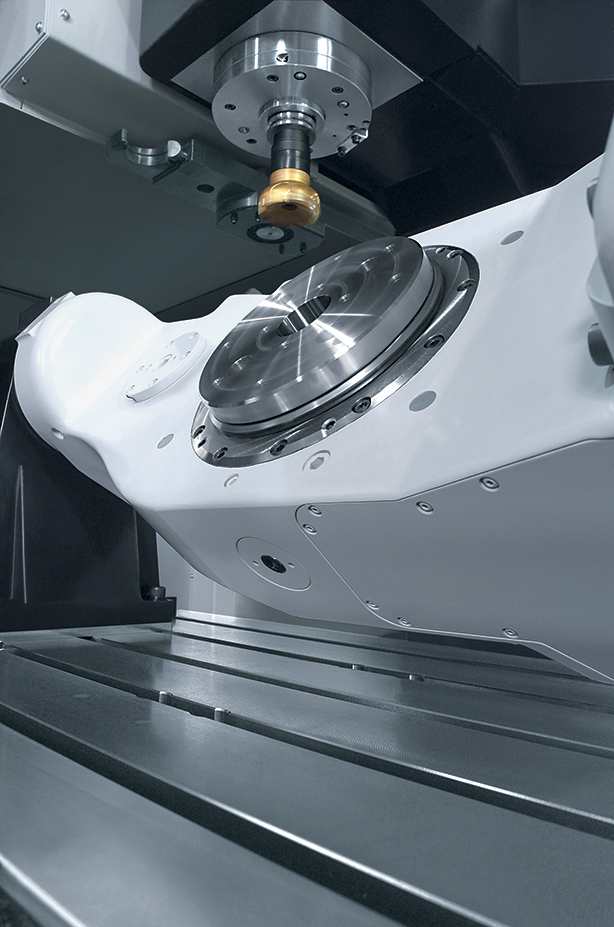

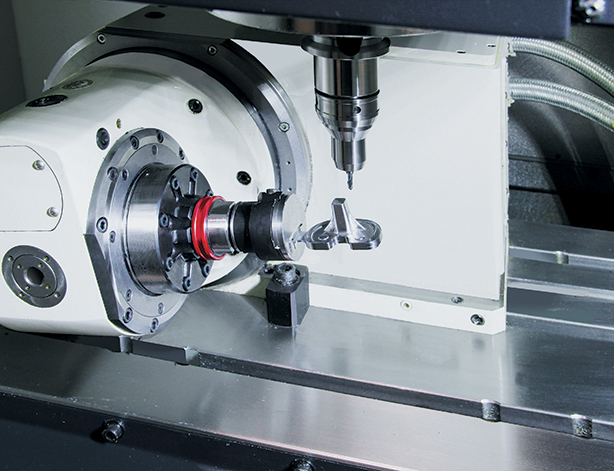

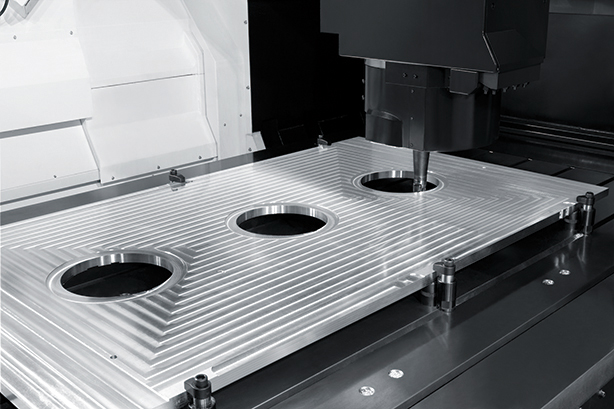

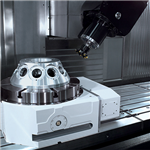

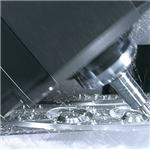

Machining, also known as milling, relies on rotary cutters to remove metal from a workpiece. Vertical machining occurs on a vertical machining center (VMC), which employs a spindle with a vertical orientation. With a vertically oriented spindle, tools stick straight down from the tool holder, and often cut across the top of a workpiece.

Why Mazak Vertical Machining Centers?

Vertical Machining Benefits

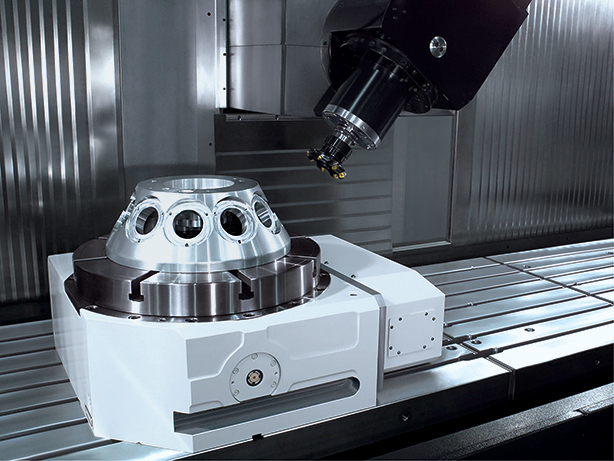

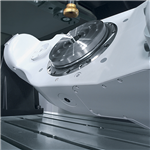

- 3-, 4- and 5-axis capabilities for infinite possibilities as to the part shapes you can process

- Temperature stability through integral cooling

- MX Hybrid Roller Guides provide durability and reliability for long-term accuracy

- On-board probing for part location and feature inspection with the cutting cycle

- User-friendly CNC controls simplify programming and increase productivity

- Pallet changers that increase spindle utilization and reduce part cycle times

A Vertical Machining Solution for Every Application Type

Whether your application calls for small or large part machining in a low- or high-volume production environment, we offer an extensive range of vertical machining centers to ensure you have the best solution for your needs with the lowest cost of ownership in the industry.

VC-Ez Series

Kentucky-built performance combines Mazak quality and reliability with space-saving efficiency at an affordable price. Cover all your machining needs with spindle options, ATC capacities and chip/coolant management solutions.

- Spindles: 12K, 15K

- Spindle Connection: CAT40

- ATC: 30 and 50 tools

- Series range: 3-Axis vertical

VCN Series

A world class series of machines that can handle everything from small lot jobs shops to high production and everything in between. The robust C-frame and moving table design exceeds expectations even in the most demanding of applications all while offering years of dependability.

- Spindles: 15K and 20K

- Spindle Connections: CAT40, CAT40/BIG PLUS, CAT50, and BT40

- ATC: 30, 48 and 60 tools

- Series range: 3-Axis vertical, 5-Axis trunnion and 2 pallet changer designs

VTC Series

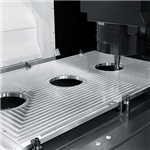

The VTC (Vertical Traveling Column Series) is a fixed table design vertical mill that offers both CAT40 and CAT50 along with multiple table sizes allowing shops the capability of machining larger workpieces with extreme rigidity and speed. Optional table partition (removable) allows the flexibility of a standard machine and that of 2 pallet changer style machine all in one.

- Spindles: 6K, 10K, 12K, 15K, 18K and 20K

- Spindle Connections: CAT40, CAT40/BIG PLUS, BT40 and CAT50

- ATC: 24, 40, and 48 tools

- Series range: 3-Axis vertical, 4-Axis rotary and optional table partition

Contact your local Mazak Representative or visit one of our Technology Centers to identify what Mazak Machining Center best fits your part-processing needs.